Machinery Compact

About GGMC

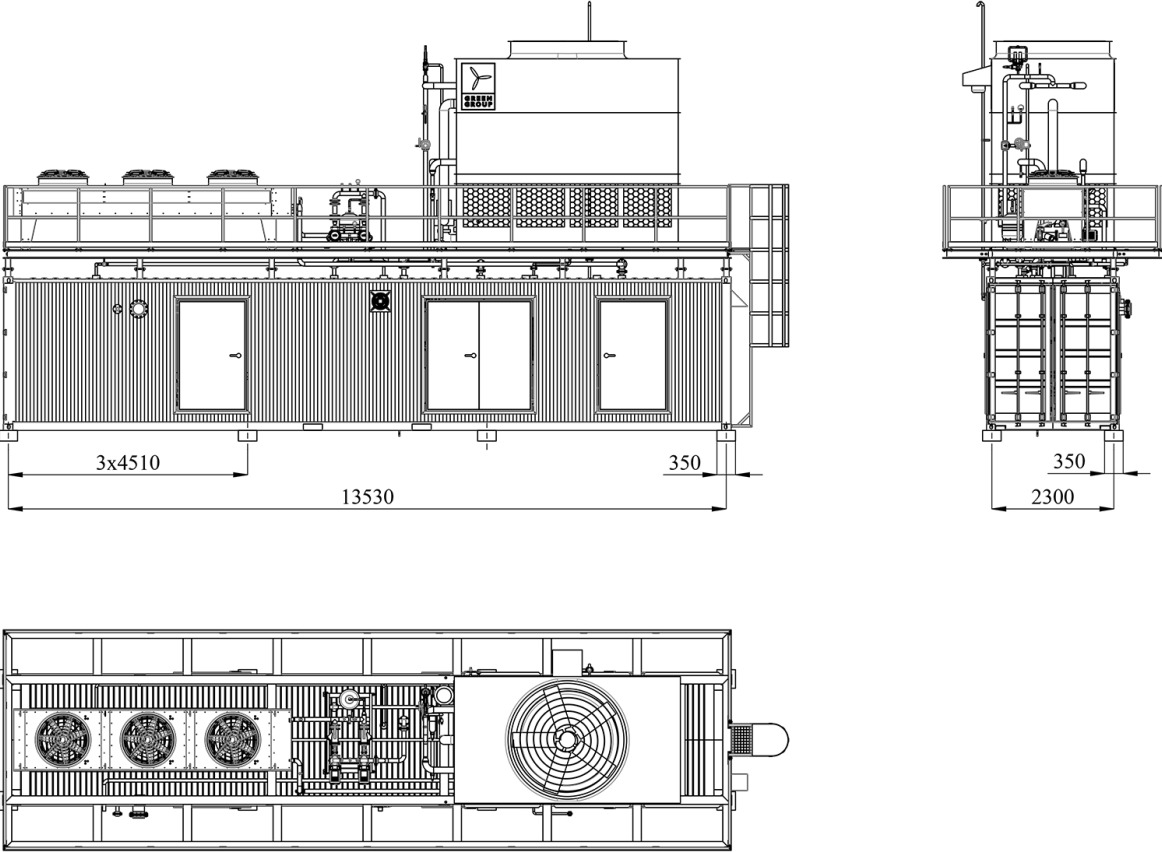

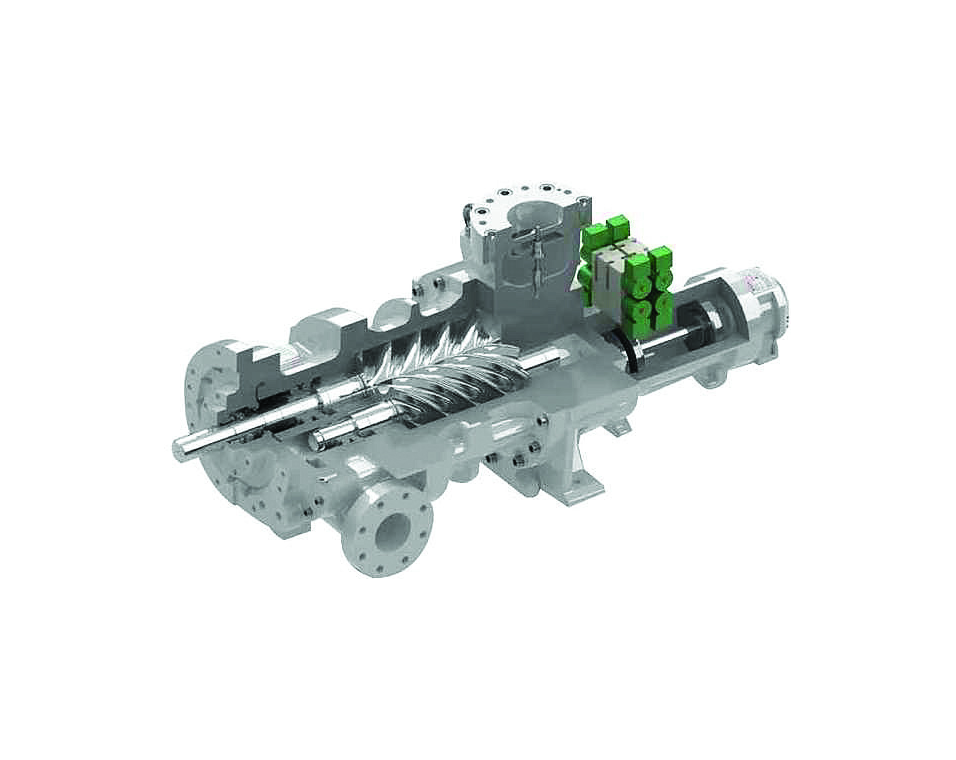

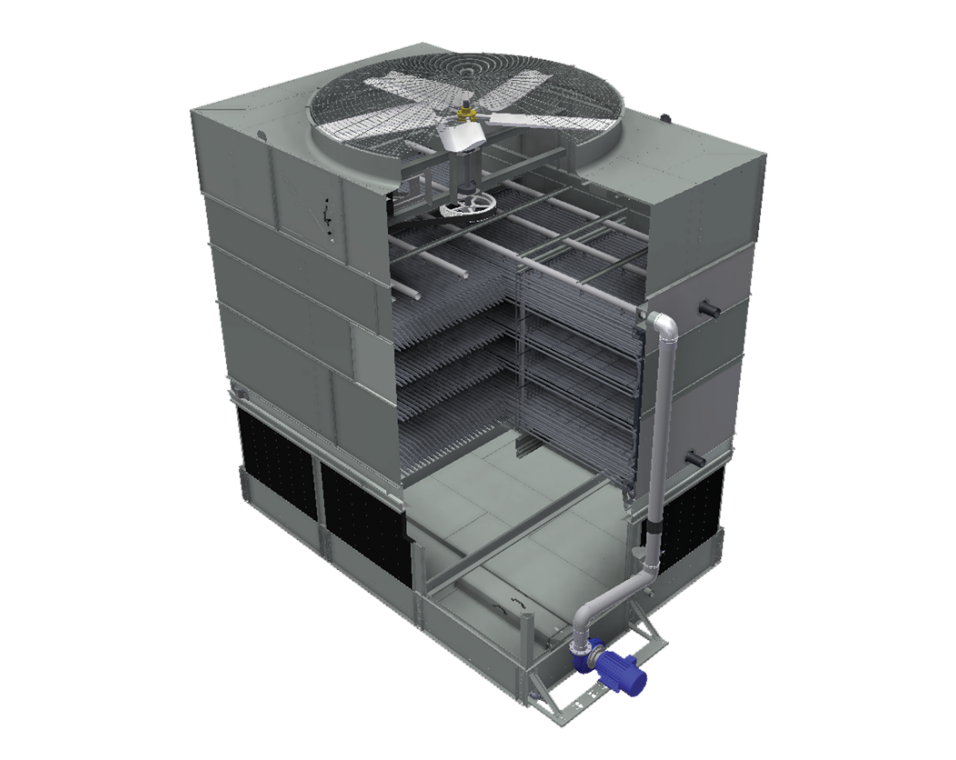

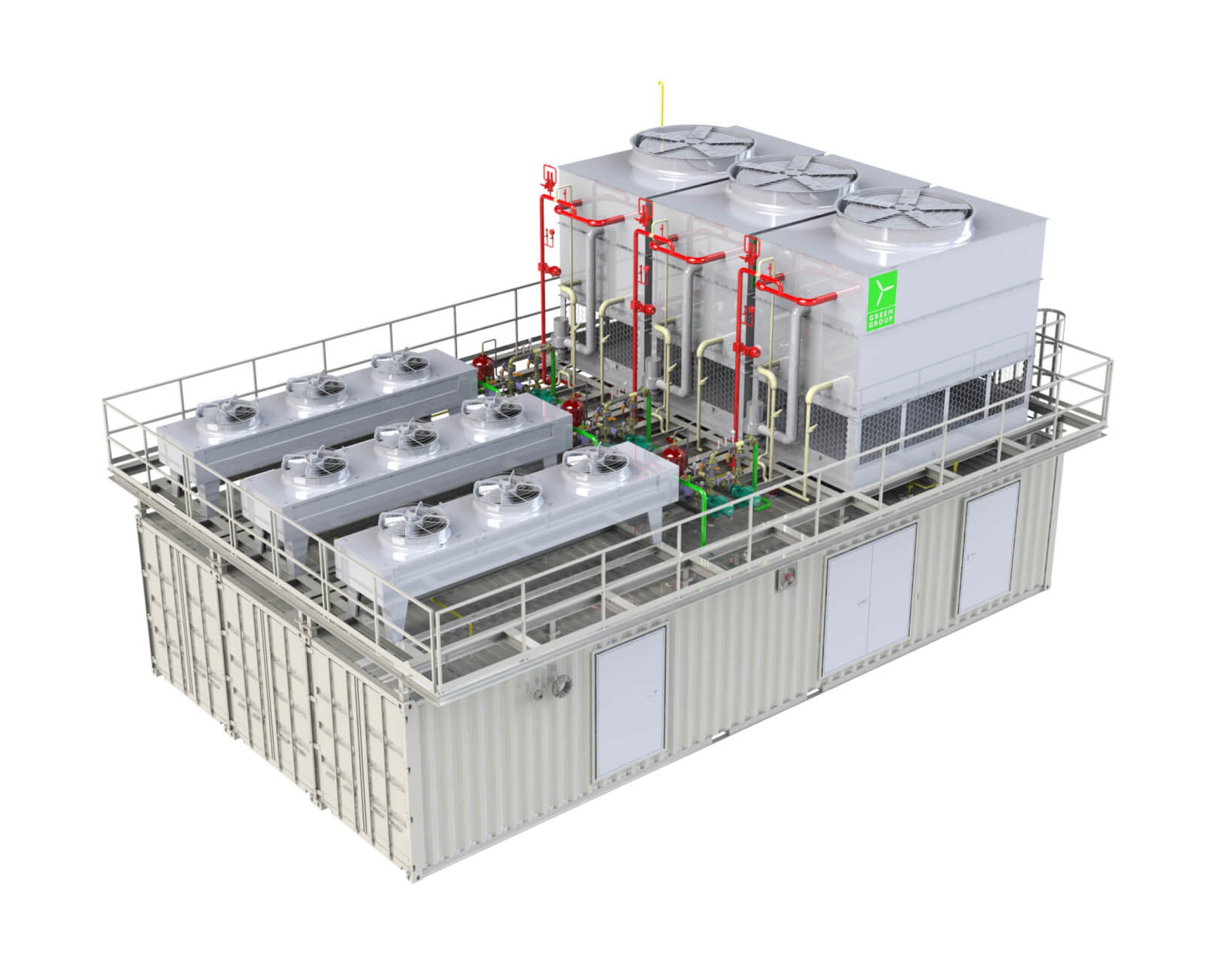

GGMC is mobile machinery developed and manufactured by the Green Group, experts in industrial refrigeration since 2006. Talking with clients we noticed that not all of them have the opportunity to build new compressor rooms. We suggest this solution, which does not require a lot of preparation from the client and can be easy integrated into any systems. All equipment is built in sections mounted inside 45 ft shipping containers and on a special platform on top of the container. Depending on logistical factors, the platform can be demounted and easily assembled again at the customer’s location.

| Model (ammonia) | FREEZING | COOLING | CHILLING | |

|---|---|---|---|---|

| Max refrigeration capacity at -40°C | Max refrigeration capacity at -10°C | Max refrigeration capacity at +2°C | ||

| GGMC 120 | 117 kW | 452 kW | 691 kW | QUOTE IT |

| GGMC 160 | 153 kW | 580 kW | 881 kW | QUOTE IT |

| GGMC 200 | 197 kW | 750 kW | 1146 kW | QUOTE IT |

| GGMC 300 | 282 kW | 1028 kW | 1194 kW | QUOTE IT |

| GGMC 400 | 370 kW | 1335 kW | 1537 kW | QUOTE IT |

| GGMC 500 | 485 kW | 1735 kW | 2596 kW | QUOTE IT |

Advantages

- Simple installation

- Saving footprint

- Reinforced frame

- Liquid resistance floor

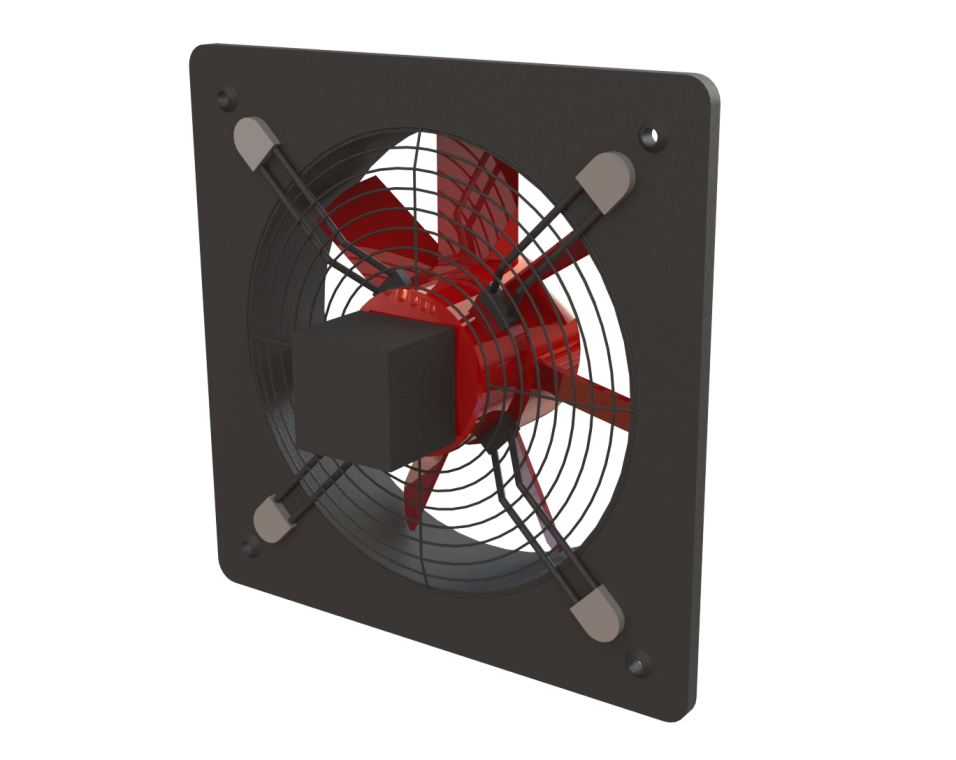

- Ventilation system

- Inside temperature control

- Leakage sensor and other safety systems

- Water treatment system

- Fully insulated pipes and components

- PED 2014/68/eu and CE approval

- Remote service support 24/7

Options

- Heat recovery

- Heat Pump

- CO2/NH3 cascade solution

- Low charge ammonia volume

- Tropic version

The 45ft HC (high cube) container standard dimensions are: L=13716 mm; W=2438 mm; H=2896 mm. Overall characteristics are shown in next table.*

| Measurement | Dimension, mm | Weight, t |

|---|---|---|

| Lenght | 14802 | |

| Width | 4130 (2065x2) | Up to 25 t (18+7) |

| Height | 6374 (3187x2) |

*All dimensions can be adjusted according to individual customer requirements.

Everything we need – few conditions for installation: